Navigating the world of medical device and pharmaceutical manufacturing can be a daunting task. For companies like KVK-Tech, compliance with regulations is not just important—it’s essential. However, despite best efforts, some businesses may find themselves facing FDA warning letters that highlight critical issues within their operations. These letters serve as serious reminders of the need for stringent quality control and adherence to Good Manufacturing Practices (cGMP). Understanding what these warnings entail and recognizing common pitfalls can help organizations steer clear of future problems. Let’s delve into the key aspects surrounding KVK-Tech warning letters and how to effectively address them before they escalate into major setbacks.

What is KVK-Tech Warning Letters?

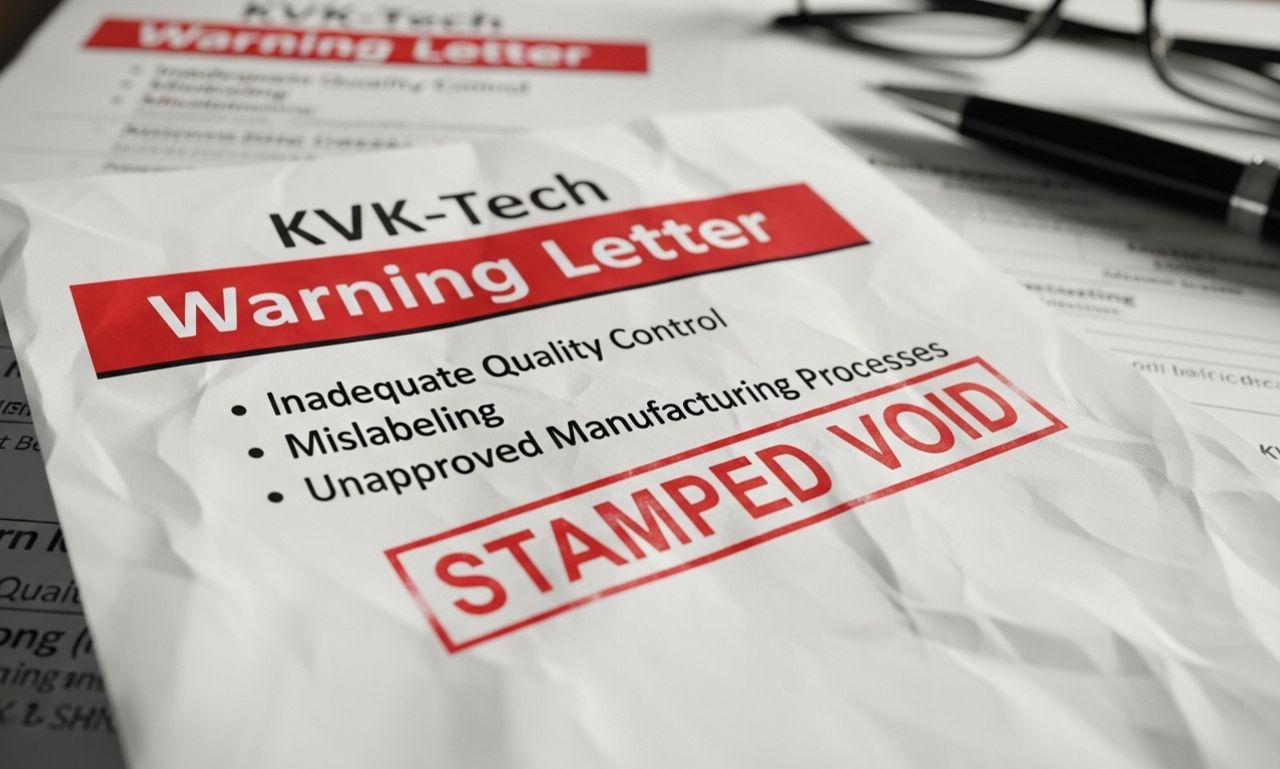

KVK-Tech warning letters are formal communications issued by the FDA to KVK-Tech, a pharmaceutical company. These letters highlight specific violations related to manufacturing practices or regulatory compliance.

When the FDA identifies potential issues during inspections, they document their findings in these letters. They serve as critical notifications that certain standards have not been met. Businesses must take them seriously and respond promptly.

The content of a warning letter usually details observed deficiencies, urging immediate corrective actions. It’s an opportunity for companies like KVK-Tech to rectify problems before facing more severe consequences.

Understanding what constitutes a KVK-Tech warning letter is essential for maintaining compliance within the industry. Addressing these concerns proactively can help safeguard both reputation and operational integrity.

Common Issues Found in KVK-Tech Warning Letters

KVK-Tech warning letters often highlight several critical issues that can jeopardize a company’s reputation and operations.

One of the most prevalent problems is the lack of quality control. Inadequate documentation can lead to significant gaps in accountability, making it difficult to trace products through their manufacturing processes.

Another common issue is insufficient testing and validation procedures. This neglect not only compromises product safety but also raises questions about compliance with regulatory standards.

Additionally, many KVK-Tech warning letters point out failures related to current Good Manufacturing Practices (cGMP). These regulations ensure that products are consistently produced and controlled according to quality standards necessary for ensuring consumer safety.

Addressing these concerns promptly is vital for maintaining trust and adherence to industry guidelines.

Lack of Quality Control and Documentation

Quality control is paramount in the manufacturing process, especially for companies like KVK-Tech. A lack of rigorous quality control can lead to significant issues, including product recalls and safety concerns.

Documentation plays a crucial role in this aspect. When proper records are not maintained, it becomes difficult to trace problems back to their source. This can result in inefficiencies and an increased risk of non-compliance with regulatory standards.

Without adequate documentation, companies may struggle during inspections or audits. The absence of clear procedures raises red flags for regulators. It’s essential to establish comprehensive quality management systems that include detailed documentation practices.

Regular training sessions for staff on the importance of quality control can help mitigate these risks. Investing time and resources into fostering a culture of accountability ensures products meet both company standards and regulatory requirements.

Inadequate Testing and Validation Processes

Inadequate testing and validation processes are a significant concern for KVK-Tech. These lapses can lead to compromised product safety and efficacy, triggering warning letters from the FDA.

When companies do not properly evaluate their products before release, they risk harming patients and eroding trust in their brand. Testing should be comprehensive, covering all aspects of a product’s performance under various conditions.

Validation is equally crucial. It ensures that manufacturing processes consistently produce quality products. A lack of rigorous validation protocols may result in subpar production practices that could have serious implications.

Implementing robust testing methodologies is essential to meet regulatory standards. This includes documenting every step taken during the process to demonstrate compliance effectively. Investing time and resources into these areas can help mitigate risks associated with inadequate practices and enhance overall quality control measures.

Failure to Follow cGMP Regulations

cGMP regulations are critical for ensuring the quality and safety of pharmaceutical products. When companies fail to adhere to these guidelines, they open themselves up to significant risks.

One major issue is inadequate facility maintenance. A clean and controlled environment is essential for preventing contamination. Neglecting this can lead to serious health hazards for consumers.

Another common violation involves insufficient training for employees. Staff must understand protocols clearly; otherwise, mistakes happen that could compromise product integrity.

Documentation also plays a vital role in compliance with cGMP standards. Missing or incomplete records can raise red flags during inspections, resulting in potential penalties or recalls.

Batch consistency is crucial. Variability from one production run to another can indicate underlying problems in manufacturing processes, further attracting scrutiny from regulatory bodies like the FDA.

How to Address KVK-Tech Warning Letters

Addressing a KVK-Tech warning letter requires immediate and thorough action. Start by reviewing the contents of the letter carefully. Understand each issue raised by the FDA to ensure all concerns are addressed adequately.

Next, assemble your team to create an action plan. Assign responsibilities for corrective measures related to quality control, testing protocols, and compliance with cGMP regulations.

Documentation is key; maintain detailed records of your responses and any changes made in processes or procedures. This not only shows your commitment but also assists in future inspections.

Consider seeking expert advice if needed. Consulting with regulatory professionals can provide insights into best practices that may have been overlooked.

Establish a robust training program for staff members. Ensuring everyone understands compliance standards can help prevent future issues from arising within your organization.

Importance of Compliance and Preventing Future Warning Letters

Compliance is essential for any organization, especially in the highly regulated field of pharmaceuticals and medical devices. It not only protects consumer safety but also enhances a company’s reputation.

Preventing future KVK-Tech warning letters hinges on a proactive approach to quality management systems. Regular audits can identify potential gaps before they become significant issues.

Training staff on current regulations ensures everyone understands their role in maintaining compliance. This creates a culture of accountability and vigilance within the organization.

Investing in robust documentation practices helps track processes effectively. This transparency allows companies to respond swiftly to any regulatory inquiries or inspections.

Adherence to guidelines fosters trust with regulators and consumers alike, paving the way for sustainable success without the looming threat of warnings disrupting operations.

Conclusion

KVK-Tech plays a significant role in the pharmaceutical and biotechnology industries. However, when faced with a KVK-Tech Warning Letters, companies must take these warnings seriously. The issues outlined in such letters often stem from lapses in quality control, inadequate testing processes, or failures to comply with current Good Manufacturing Practices (cGMP).

Addressing these concerns promptly is crucial for maintaining compliance and safeguarding your company’s reputation. By focusing on improving documentation practices, enhancing testing protocols, and ensuring adherence to regulatory standards, businesses can not only resolve past issues but also prevent future problems.

Maintaining stringent quality assurance measures is vital for sustaining operational integrity. A proactive approach will ultimately enhance product safety and efficacy while fostering trust among consumers and regulators alike. Taking steps today can pave the way for a more compliant tomorrow within the industry landscape influenced by KVK-Tech regulations.